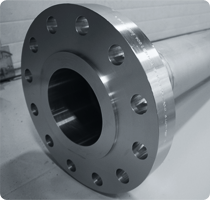

Passivation / Pickling

ProSolutions has the capability to meet all your pickling and passivation needs. We can pickle any part that can be transported to our facility. If the part can’t be shipped, our on-site crew and capabilities allow us to process parts outside our facility. Our Passivation and Pickling services include the following main processes: Stainless steel pickling, stainless steel passivation, and carbon steel pickling.

Stainless Steel Pickling

Stainless steel can corrode in service if there is contamination of the surface. Both pickling and passivation are chemical treatments applied to the surface of stainless steel to remove contaminants and assist in the formation of a continuous chromium-oxide, passive film. Pickling and passivation are both acid treatments and neither will remove grease or oil. If the fabrication is dirty, it may be necessary to use a detergent or alkaline clean before pickling or passivation.

Stainless steel can corrode in service if there is contamination of the surface. Both pickling and passivation are chemical treatments applied to the surface of stainless steel to remove contaminants and assist in the formation of a continuous chromium-oxide, passive film. Pickling and passivation are both acid treatments and neither will remove grease or oil. If the fabrication is dirty, it may be necessary to use a detergent or alkaline clean before pickling or passivation.

Pickling is the removal of any high temperature scale and any adjacent low chromium layer of metal from the surface of stainless steel by chemical means.

Where the steel has been heated by welding, heat treatments or other means, to the point where a coloured oxide layer can be seen, there is a chromium depleted layer on the surface of the steel underneath the oxide layer. The lower chromium content gives lower corrosion resistance. To restore the best corrosion resistant performance, the damaged metal layer must be removed, exposing a fully alloyed stainless steel surface. Mechanical removal may leave abrasive or other particles embedded (interfering with corrosion performance) or may be impractical, so chemical means are usually employed.

Procedures incorporating pickling solutions of nitric (HNO3) and hydrofluoric (HF) acids remove the scale and the underlying chromium depleted layer and restore the corrosion resistance. Pickling solutions also remove contaminants such as ferrous and ferric oxide particles. Pickling solutions other than mixtures of nitric and hydrofluoric acids exist and can be used for specialized applications.Pickling pastes, where the solution is mixed with an inert carrier, are commonly used to treat selected areas such as welds.

Pickling involves metal removal and a change or dulling in the visual brightness of the metal.Electropolishing is a useful alternative to pickling. Metal removal is achieved, but usually results in a bright, smooth and more highly corrosion resistant finish.

Stainless Steel Passivation

Passivation is the treatment of the surface of stainless steels, often with acid solutions (or pastes), to remove contaminants and promote the formation of the passive film on a freshly created surface (eg through grinding, machining or mechanical damage).

Common passivation treatments include nitric acid (HNO3) solutions or pastes which will clean the steel surface of free iron contaminants. Care must be taken in selecting and using passivation treatments to ensure the selected treatment will target the contaminant. Passivation will also aid in the rapid development of the passive oxide film on the steel’s surface. Passivation does not usually result in a marked change in appearance of the steel surface.

Both pickling and passivation solutions can employ dangerous acids that can damage both the operator and the environment if not handled correctly. Stainless pickling acids are highly corrosive to carbon steel.It is essential that all acids are thoroughly removed by rinsing the component after completing the process. Residual hydrofluoric acid will initiate pitting corrosion.It may be advantageous to neutralise the acid with an alkali before the rinsing step.

ASTM A380 Standard Practice for Cleaning, Descaling and Passivation of Stainless Steel Parts, Equipment and Systems is a valuable source of information on pickling and passivation treatments.

The corrosion resistance of the stainless steel is affected by the roughness of the surface after polishing, with a marked decrease of the corrosion resistance as the surface roughness increases above a Ra value of about 0.5 micrometres. This roughly corresponds to the surface produced by grinding with 320 grit abrasives.Either passivation or electropolishing can be used to improve the corrosion resistance of mechanically polished surfaces.

Carbon Steel Pickling

Before pickling, grease, oil, organic contaminants and protective coatings must be removed by means of a water-based alkaline product.

To remove oxide layers, annealing skin, mill scale, and corrosion products, the material is pickled with inhibited hydrochloric acid. The pickling time depends on the nature and thickness of the contamination.

After pickling, the material is internally and externally flushed with a high pressure power washer and neutralizing solutions.